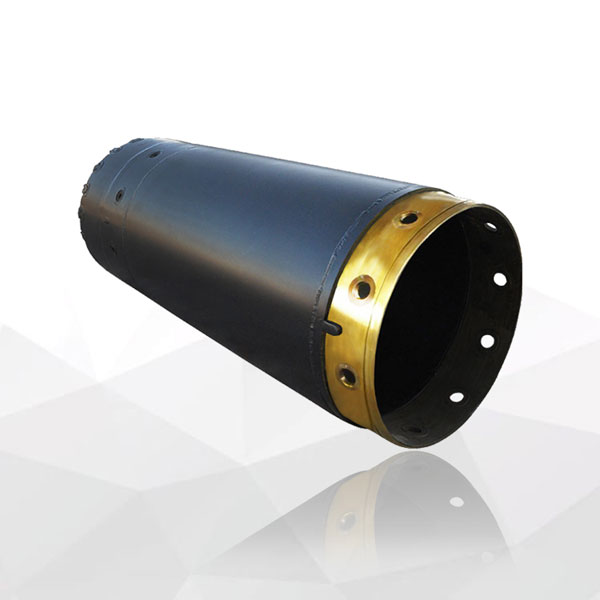

Features:

1.The casings are made of double-wall pipes

2.Different casing section length from 1m to 6m optional

3.Casing connections on both side with female or male part and conical or threaded rings. Screw connections with seal and O-rings.

4.Custom-fit pipe connections for quick positioning and screwing together of pipes.

Descriptions:

1.The casings are designed to perform cased holes, especially for the construction of bored piles by rotary drilling rigs.

2.The casing joint with high machining accuracy ensures a fast replacement and bolting of the casing as well as the best for force transmission effect.

Technical Parameters:

| Double-wall Casing Tube | |||||||||||||||||||||

| Dia. | Length |

Casing-wall THK-1 |

Casing-wall THK-2 |

Total THK |

Bolt QTY |

||||||||||||||||

| D1/D2 | 1m | 2m | 3m | 4m | 5m | 6m | a1 | a2 | t2 | bolts | |||||||||||

| (mm) | Weight(kg) | (mm) | (mm) | (pcs) | |||||||||||||||||

| 620/540 | 403 | 739 | 1074 | 1411 | 1747 | 2081 | 12 | 8 | 40 | 8 | |||||||||||

| 750/670 | 492 | 902 | 1311 | 1722 | 2131 | 2540 | 12 | 8 | 40 | 10 | |||||||||||

| 880/800 | 585 | 1069 | 1552 | 2036 | 2520 | 3005 | 12 | 8 | 40 | 10 | |||||||||||

| 1000/920 | 669 | 1221 | 1773 | 2328 | 2877 | 3429 | 12 | 8 | 40 | 10 | |||||||||||

| 1180/1100 | 844 | 1580 | 2316 | 3052 | 3787 | 4522 | 16 | 8 | 40 | 12 | |||||||||||

| 1200/1120 | 872 | 1620 | 2370 | 3120 | 3870 | 4620 | 16 | 8 | 40 | 12 | |||||||||||

| 1300/1200 | 933 | 1746 | 2558 | 3372 | 4184 | 4996 | 16 | 10 | 40 | 12 | |||||||||||

| 1500/1400 | 1433 | 2628 | 3817 | 5009 | 6210 | 7393 | 20 | 10 | 50 | 12 | |||||||||||

| 1800/1700 | 1730 | 3166 | 4602 | 6038 | 7474 | 8910 | 20 | 10 | 50 | 16 | |||||||||||

| 2000/1880 | 2450 | 4280 | 6110 | 7940 | 9770 | 11600 | 20 | 15 | 60 | 12 | |||||||||||

| 2200/2080 | 2700 | 4720 | 6740 | 8760 | 10780 | 12800 | 20 | 15 | 60 | 12 | |||||||||||

| 2500/2380 | 2960 | 5240 | 7520 | 9800 | 12080 | 14360 | 20 | 15 | 60 | 16 | |||||||||||

Advantages:

1.No mud discharge, truly green and environmental protection.

2.Solve the problem of the wall protection and drilling of the rotary drilling rig in the complex sand layer, fluid plastic silt layer, backfill layer, pebble layer, etc.

3.The guiding effect of the casing itself can be used to control the verticality of the pile.

4.There is no effect of mud and sediment caused by mud wall protection on the weakening of the bearing capacity of the bored pile, so that the lateral friction resistance and bearing capacity of the pile are greatly improved compared with other pile types.

5.Avoid the quality problems such as shrinkage, broken piles and concrete segregation that may occur in general cast-in-place piles.

6.The problem of hole wall collapse of the upper unstable section caused by suction and disturbance during drilling is completely avoided.