Introduction

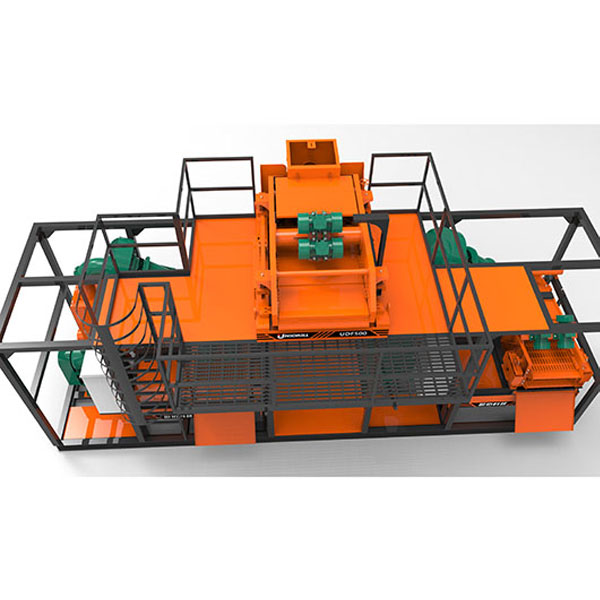

UDF-Desanding plant is widely used in the purification and recycling of slurry for the construction of hydropower, continuous concrete wall, slurry shield tunnel, etc. the equipment is increasingly becoming a necessity of civilized construction since it not only can cut down construcion cost, but also can reduce the pollution of the environment. It can provide you with main advantages as following

Main Applications

1. By fully purifying slurry, it is favorable to control slurry index, reduce drill stucking phenomena, and improve drilling quality.

2. By thoroughly separating the slag and soil, it is favorable to enhance drilling efficiency.

3. By realizing the repetition use of slurry, it can save slurry making materials and thus reduce the construction cost.

4. By adopting the technique of close-cycle purification and low water content of removed slag, it is favorable to reduce

Feature

1. High mud handling capacity, sand can be removed efficiently.

2. The oscillating screen has many advantages such as easy operation, low trouble rate, convenient installation and maintenance

3 .Slagcharge screened by advanced straight-line oscillating system is effectively dewatered

4. The adjustable vibrating force, angle and mesh size of the oscillating screen enable the equipment possess a high screening efficiency in all kind of strata.

5. The high screening efficiency of the machine can excellently support drillers raise bore and advance in different strata.

6. Energy saving efficiency is significant since the power consumption of the oscillating motor is low.

7. Low operation noise of oscillating screen is favorable to improve the working condition.

8. The abrasion and corrosion resisting slurry pump has many advantages such as advanced centrifugal designing, optimal structure, stable operation and convenient maintenance.

9. The thick, abrasion-resisting parts and special designed bracket enable the pump to convey corrosive and abrasive slurry with high density.

10. The hydraulic cyclone with advanced structural technology can efficiently separate sand from slurry. Moreover, it features in light weight, corrosion and abrasion resisting material, so it can work stably in the worst condition without maintenance.

11. The special designed automatic liquid-level balancing device can not only keep the liquid-level of the slurry reservoir stable, but also realized the reprocessing of mud, so the purification quality can be further enhanced.

12. The unique recoiling device can prevent slurry reservoir from silting and flooding in order to ensure the machine work smoothly without maintenance for a long time.

Parameters

| UDF-50 | UDF-100 | UDF-200 | UDF-250 | UDF-250A | UDF-250C | UDF-500 | |||||||||

| Slurry feed capacity(m3/h) | 50 | 100 | 200 | 250 | 250 | 250 | 500 | ||||||||

| Cut point(μm) | 50 | 30 | 60 | 60 | 60 | 60 | 60 | ||||||||

| Solids feed capacity | 10-25 | 25-50 | 25-80 | 25-80 | 25-80 | 25-80 | 75-240 | ||||||||

| Total capacity(kw) | 17.2 | 24.2 | 48 | 58 | 58 | 58 | 119 | ||||||||

| Dismension(m) | 2.30×1.25 | 3.00×1.90 | 3.54×2.25 | 3.54×2.25 | 3.54×2.25 | 3.54×2.25 | 10.48×3.36 | ||||||||

| ×2.46 | ×2.30 | ×2.83 | ×2.83 | ×2.83 | ×2.83 | ×4.68 | |||||||||

| Total weight(kg) | 2100 | 2700 | 4800 | 6350 | 6350 | 6350 | 12500 | ||||||||