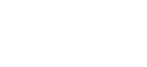

Features:

1.Adjustable cutting arms can meet the specific requirements of different reaming diameters

2.After reaming the bore hole, convey spoil with drilling bucket or cleaning bucket

3.Cutting arms are easy to spread and retract

4.It is easy to maintain the box-type structure

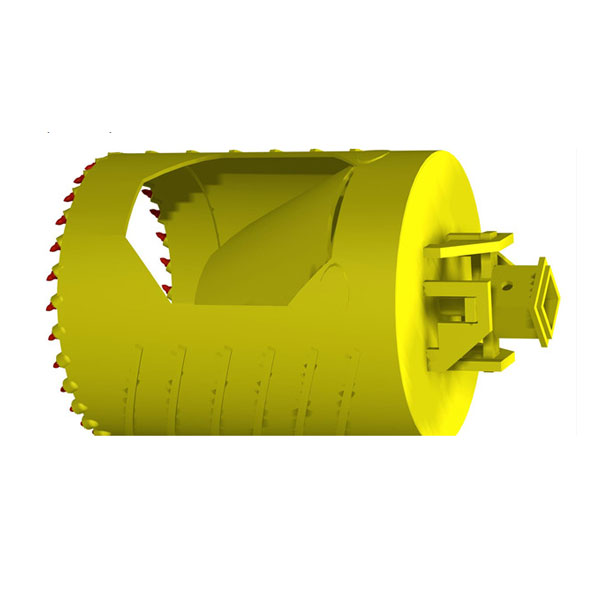

Descriptions:

1.Drilling buckets are mainly used for drilling water-bearing sandy soil, sludge, clay, muddy sub clay, sandy gravel, cobble, and weathered soft formation.

2.The bucket can be designed into cylindrical type and conical type according to bucket diameter, type of drilling rig and soil conditions.

3.The welding angle of bucket teeth can be designed according to formation conditions so that the drilling buckets can keep high efficiency of soil cutting amount in any formation conditions.

4.The bottom cover is made of high-strength Mn plate, and the cutting edge includes single-layer type and double-layer type.

5.The soil inlet also includes single-bottom type and double-bottom type.

Technical Parameters:

| Belling Bucket | ||||||||||||||

| Cutting Arms Diameter | Bucket HIT | Swing No | Limit Hole No | Teeth No | Reaming Multiples | Weight(KGS) | ||||||||

| φ600--1200 | 3050 | 2 | 2 | 28 | 1.5-2.0 | 1190 | ||||||||

| φ800--1600 | 3100 | 2 | 3 | 28 | 1.5-2.0 | 1310 | ||||||||

| φ900--1800 | 3050 | 2 | 3 | 28 | 1.5-2.0 | 1500 | ||||||||

| φ1000--2000 | 3050 | 2 | 3 | 30 | 1.5-2.0 | 1650 | ||||||||

| φ1100--2200 | 3050 | 2 | 4 | 30 | 1.5-2.0 | 1880 | ||||||||

| φ1200--2400 | 3050 | 2 | 4 | 30 | 1.5-2.0 | 2350 | ||||||||

| φ1500--3000 | 4000 | 2 | 4 | 32 | 1.5-2.0 | 3600 | ||||||||

| Customizable Items: | ||||||||||||||

| Other cutting diameters likeΦ950, Φ1050mm can be customized. | ||||||||||||||

| Key component reinforce can be strengthened. | ||||||||||||||

| Swing type can be customized, double swing or triple swing. | ||||||||||||||

| Key box can be customized, 130*130,150*150,200*200 etc. | ||||||||||||||

| Limit hole quantity can be customized, more limit holes can be added to meet different reaming diameters. | ||||||||||||||

Advantages:

1.High quality raw materials and high steel strength

2.Simple operation

3.High wear resistance

4.High drilling efficiency

5.High hardness

6.Good roundness of the cylinder

7.Long service life